Welcome to another blog exploring exceptional business outcomes achieved through targeted transformation strategies! In this edition, we dive into the world of Manufacturing. We’ll explore how companies leverage HCL Total Experience (TX) to deliver tangible results across their business operations.

Historically, manufacturers have thrived by understanding their end customers. This “direct-to-consumer” connection allows them to maintain relevance, drive consumption, and anticipate future needs - a vital signal in today’s ever-changing market. While this translates to success on the sales side (including retail partnerships), optimizing production and after-market operations is equally important. Here’s where digitization comes in: streamlining processes for boosted productivity, efficiency, and reduced waste. Here’s my summary of the challenges.

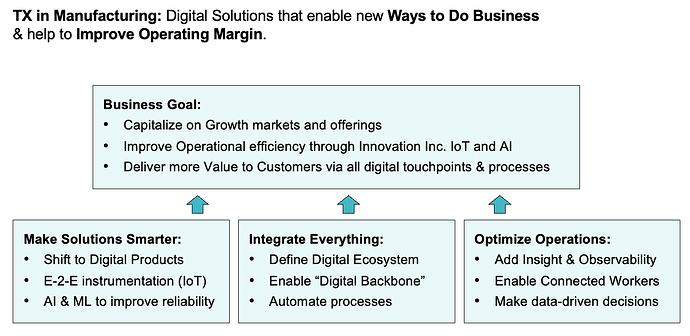

Hence, let’s explore how HCL Total Experience is being used to deliver substantial business value:

- Industry 4.0 - Smart Factories and Smarter Workers: TX can streamline inspections and replenishment by replacing manual tasks with user-friendly mobile apps for inspections, inventory checks, and order requests. In addition, TX empowers real-time business by providing executives with mobile dashboards that deliver a holistic view of manufacturing, inventory, and sales performance. Combined with external demand insights, manufacturers can use data-driven decision-making to optimize operations for anticipated demand. One consumer product manufacturer used TX to help its C-suite deliver predictability and reduce costs.

- AI and Machine Learning for True Observability: TX can leverage real-time insights from production operations coming from IoT edge devices coupled to equipment, robots, and worker activities to benefit the business. Specifically, machine-learning-derived insights can help with predictive maintenance schedules and improved fault diagnosis, resulting in less lost production and more robust supply chain management. For example, one manufacturer used TX to ensure that digital locks became part of their operators’ processes and that only the right raw materials were always used.

- New Manufacturing Techniques (e.g., 3D Printing): Competitive prototyping and manufacturing isn’t for everyone. However, it’s increasingly a strong use case for healthcare, building products, and automotive manufacturers. TX can enable lower-volume manufacturers to create unique prototypes and products that offer a competitive edge to easily connect with their markets and customers, reduce inventory on hand and create new service-level agreements (SLAs) with faster fulfilment. For example, one manufacturer used TX to enable surgeons to request custom replacement cranial parts directly for their patients, thereby saving time and effort.

- Digitalizing How You Sell: for a manufacturer supporting their business development reps, digitizing can have an impact. For example, ensuring the in-store promotional activities such as maximizing shelf space and promotional effectiveness are carried out correctly, and evidence is captured at the retailer. In addition, one manufacturer equipped all their business development representatives with mobile apps to automate their tasks, including route optimization extensions to save time and reduce costs.

- Leveraging Direct-to-Consumer (D2C) Channels: Staying relevant to customers is on the mind of every manufacturer, and one of the ways to accomplish this is to have direct-to-consumer channels for your business. This approach can be used to build brand loyalty, open up new markets, or add product extensions. For example, one consumer product manufacturer facilitated a unified customer experience with seamless customer journeys across online and brick-and-mortar businesses with geo-fenced promotions to drive purchases to authorized retailers, fulfilling needs and deepening consumption.

As always, our Total Experience mission is to deliver a tailored outcome that solves business challenges faster. For IT, our goal is to help them reduce complexity, delivery times and cost compared to other platform approaches with the adoption of TX. I hope you enjoyed what we are learning for our amazing customers.